I have been into electronics, almost as long as I can remember walking around. Well, not quite that early on, but electronics has been a big part of my career and life – since before I was a teen. We’ll be generous and say 40+ years.

Most people will tell you that Aquaponics is a combination of Hydroponics – growing plants in a soil-less environment with Aquatics – fish, aquariums or fish farming. For me, the ‘onics’ also includes electronics.

My first major Aquaponics project was the Tent and barrels. I began the electronics part using the Arduino micro-controller platform, xBee wireless radios, and my existing IT infrastructure of Microsoft SQL servers to create a multi-node, wireless electronic monitoring system for my garden and tanks. I created a small wireless network that monitored ‘The Ponds’ and ‘The Barrels’.

As this is an introductory article, I won’t go into heavy detail, but suffice it to say, future posts will cover my design ideas, implementation, lessons learned and ideas for the future.

2016-03-11 Update

After much angst and re-design, I have my backyard monitoring system back on line. If you have read some of my other posts, my current backyard aquaponics configuration consists of two fish tanks (the box tank 200+ gallons and the refrigerator tank 80+ gallons) and one growbed (the buckets).

My current monitoring configuration is temperature (ambient air and three liquid), humidity and pressure. Upcoming sensors will monitor water level and ambient light. This is hosted locally on the monitor node hardware and can be viewed through wireless on my internal network – I am not planning on making this publicly accessible. I am planning on programming alarm levels so I can be alerted to important condition changes. For instance, the refrigerator tank has a fast evaporation level and also being a smaller system has to be topped up every three days or so. It would be nice to get a text to my cell phone telling me if the water level is too low. A burned out pump costs $40 to replace and that has happened once in the last couple of years and there have been plenty of close calls.

As a side note, if you are thinking an aquaponics system is low maintenance, you had better consider a change of thinking. There are many more moving parts and things that can go wrong versus a traditional raised bed garden. I just think this is way more fun.

Hardware: Raspberry Pi 3 (yes, brand new) running Raspbian Jessie, 8GB SD card. Dry sensor is a BME280 I2C sensor and the water temps are read using three DS18S20B sensors in waterproof stainless steel housings with 6′ cables to the sensor box.

Software: I use Apache with PHP for the web front end, Python scripts running on Cron jobs every five minutes to poll the sensors and then storing the data into a MySQL database. I utilize KoolPHP scripts to help with the charting and database editing needs. I can also see the status of the sensors and can see if any are off-line.

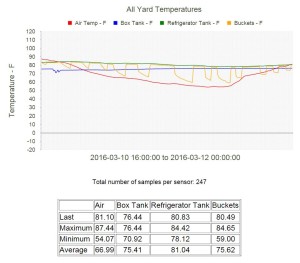

I’ve created seven different reports with graphs that allow me to select a data/time range for the different sensors. Below is a snapshot of a chart of the last 20 hours showing ambient air temp, and the three liquid temperatures.

I decided I wanted to monitor the bucket water temperature as its own data stream because although it is being fed from the refrigerator tank, it does sit dormant during the times that the pump is off. As you can see from the orange line on the chart, I can get valuable data from this reading.

Another design change – originally, I purchased and built a 3D printer with the intent of creating custom project boxes. Disappointingly, though, the boxes did not prove to be robust enough to withstand constant installation/de-installation. I decided to re-box the controller and sensor modules in SMT electrical boxes that are substantially stronger and can be made completely weatherproof if needed. Currently, they are mounted in an unexposed area just under the trough. Pictures and details to follow.

Seeing the actual temp data on the box tank (blue line) is totally awesome as this validates the construction/insulation model used. I am surprised the refrigerator tank varied as much as it did since it uses the insulation of the fridge. Granted, there is about three times more water in the box tank compared to the refrigerator, so that says something about the stability of water temperature in a bigger mass of water. Note: the funny looking hiccup at the beginning of the blue line is me doing a 40 gallon water change. We will see how things go over the next few months into our hot summer.